Waiting for an epoxy garage coating to dry can test anyone’s patience, especially when you’re looking forward to using the space again. What should take a day or two can sometimes stretch out far longer than expected, leaving you wondering what went wrong and whether something needs to be redone.

The drying time of epoxy isn’t just about the product itself. It depends on a bunch of different things. Weather, mixing methods, and even how the floor was cleaned can all play a part. Figuring out what’s causing the delay is the first step to fixing it. Once you know what’s slowing things down, you can stop the problem at its source instead of just waiting it out.

Common Reasons For Slow Drying

There are a few usual suspects when an epoxy garage floor won’t dry on time. Some rely on climate, some come down to prep, and others are all about the tools and method used during the job. If you’ve ever found yourself pacing around the garage, wondering why the floor’s still tacky, here are some things worth checking.

Temperature and Humidity

Epoxy reacts differently depending on the environment. If you apply it in cold weather or on a humid day, the drying time stretches out. Warm conditions help the solvents evaporate and speed up the curing process. On the other hand, cool or damp conditions tend to stall that reaction.

For best results, try applying epoxy when the temperature is between 15°C and 30°C, with low humidity. Avoid days right after rain or when there’s moisture in the air. If you’re stuck with a narrow window, you might use fans or heaters to stabilise the space before and during the job.

Improper Mixing

Mixing epoxy isn’t like stirring paint. You’ve got to follow the product’s exact ratio, usually a mix of resin and hardener. Too much of one or the other, and the chemical reaction won’t work properly. That can leave the surface sticky even after the full recommended drying time.

Common mixing mistakes include:

– Not scraping the sides and bottom of the mixing container

– Mixing too fast and adding bubbles to the mixture

– Guessing the quantities instead of using proper measuring tools

Stick with the instructions printed on the product’s label. A small mistake here can cause a big delay later.

Inadequate Ventilation

Airflow makes a big difference when it comes to drying. Without proper ventilation, solvent fumes don’t escape, and the curing process slows. Epoxy coatings always dry faster in well-ventilated spaces.

To improve airflow, you can:

– Open the garage door and windows

– Use pedestal or box fans to keep fresh air moving

– Point fans away from the floor so you don’t stir up dust

If the space is sealed up tight, drying will take much longer than it needs to.

Surface Preparation Issues

Prepping the floor is just as important as applying the coating. A poorly prepared floor won’t just affect how well the epoxy sticks. It also plays a big part in how evenly and quickly it cures.

Importance of Cleaning

Grease, oil, dust, or any kind of debris can mess with the bond between the floor and the epoxy. Even leftover soap or old cleaner residue can act like a barrier, leaving behind patches that stay soft or sticky.

Before applying epoxy, the surface should be:

– Swept and vacuumed to remove all dust

– Scrubbed with a degreaser to lift away oil

– Rinsed with clean water and left to dry properly

Skipping these steps might not seem like a big deal, but they can mean the difference between a floor that dries in two days and one that stays tacky well past the weekend.

Surface Moisture

Even if the surface feels dry, water trapped inside the concrete slab can stop epoxy from curing correctly. That moisture can rise during drying and get trapped under the coating.

To avoid this:

– Use a moisture meter to check the slab beforehand

– Try the plastic sheet test: tape clear plastic to the floor and leave it for 24 hours to see if water forms underneath

– Let the surface dry out fully before starting, using dehumidifiers if needed

Application Techniques That Impact Dry Time

How the epoxy is applied can change everything. Even with solid prep and the right weather, poor technique can still cause drying delays.

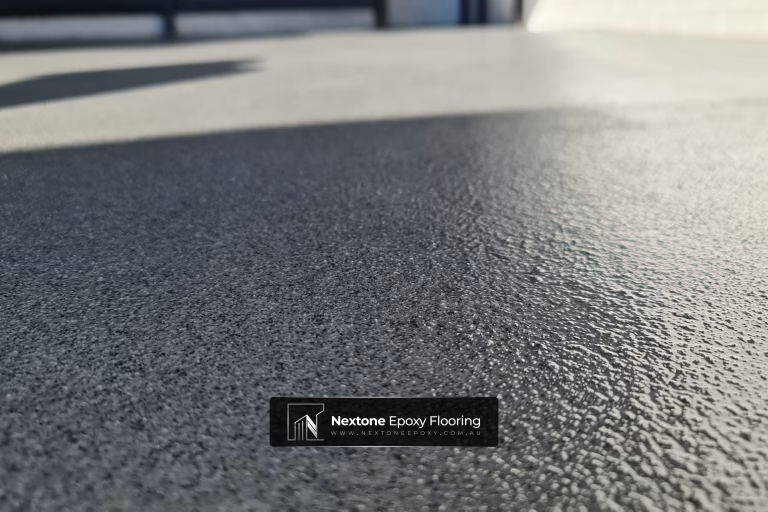

Thickness of Coating

One common mistake is putting on a coat that’s too thick. People think thicker means tougher, but it actually slows curing. The product forms a skin on top while staying soft underneath, which can trap moisture or even cause peeling later on.

Most garage coatings should be about 1–2 millimetres thick per layer, depending on the type of epoxy used. Following what the product manufacturer recommends is always better than guessing. If your floor is rough and you’re tempted to lay it on thick, consider repairing the surface first.

Use of Primers and Proper Tools

Primers help the epoxy grip better and often make curing faster by creating a consistent base. Without one, epoxy has a harder time bonding, especially on porous or uneven concrete.

Using the wrong tools is another common issue. Low-grade rollers or trowels can create uneven layers and leave pools of product. Those areas take longer to dry.

Here are some good options:

– 10–12mm nap rollers made for resin products

– Spike rollers to help remove air bubbles

– Notched squeegees for smooth coating spread

– Shoe spikes if you need to walk on the wet floor

Every tool should suit the product and the floor. Using the right gear helps get that even finish without delays.

Creating A Controlled Drying Environment

Once the epoxy is applied, the next step is creating a solid environment for it to cure. If temperature or moisture jump around during the curing stage, it can lead to uneven results and longer dry times.

To control the environment:

– Seal off the garage to stop dust settling on the surface

– Use portable heaters if it drops below 15°C

– Set up a dehumidifier if indoor moisture levels are high

– Keep a steady airflow using fans or slightly open windows

Don’t rush things. Some coatings feel dry after a day but still need more time underneath. Stepping on them early can leave marks or even wreck the surface. Stick to the full curing time mentioned on the product label, usually around 24 to 72 hours depending on conditions.

Even with everything done right, sometimes drying takes longer than it should. There could be an unknown issue with the concrete, or maybe the mix ratio was slightly off. At that point, it’s best to let a professional take a look and sort it out fast before more problems pop up.

Make Drying Time Work in Your Favour

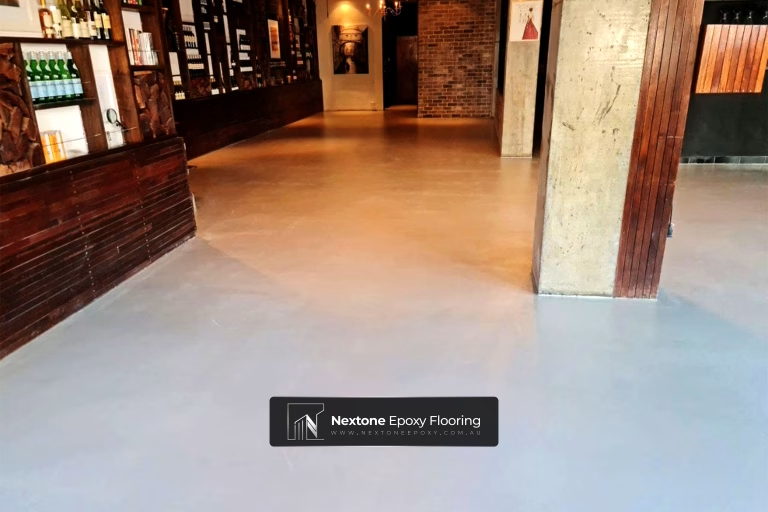

Getting epoxy onto your garage floor is a smart way to improve both its look and function. But a finish that takes forever to dry can turn into a major headache. Whether it’s the temperature, poor prep, bad airflow, or just too thick a layer, there’s usually a clear reason behind the hold-up.

By catching these causes early and taking your time with prep and setup, you’ll steer clear of sticky floors and wasted effort. Clean the surface well, mix carefully, and make sure you’re using the right tools in the right conditions. A steady environment goes a long way once the epoxy is down.

And if you’re still stuck waiting days for your floor to cure, it might be time to call in the pros. They’ll get the job done right and make sure your garage coating dries properly and looks spot-on from the start.

Ensure your epoxy garage coating is correctly done and dried without any headaches by seeking guidance from seasoned professionals. To explore how Nextone can enhance your garage floor’s durability and appearance, learn more about expert epoxy garage coating in New South Wales. Our team’s expertise and proven methods ensure a quality finish that meets both functional and aesthetic needs.