Spider web cracks on your epoxy floor might look like minor surface imperfections, but they’re often a sign that something isn’t quite right underneath. These fine, web-like cracks can show up in random patterns and are usually caused by stress. While they may start small, they can lead to bigger problems if not dealt with early, especially in busy areas like workshops, garages, or industrial floors.

Quickly addressing these cracks helps keep your floors safe and neat. It also stops moisture, dust, or dirt from creeping in and making things worse. Whether your space is residential, commercial, or industrial, fixing surface cracks early extends your floor’s life. If you’re starting to see signs of damage, epoxy floor installation in New South Wales can provide lasting results.

What Causes Spider Web Cracks in Epoxy Floors?

There’s often more than one thing that causes spider web cracks in epoxy coatings. These cracks tend to show up where stress has been building on the surface or underneath the floor.

Some common reasons for spider web cracking include:

– Movement in the underlying concrete slab

– Temperature changes, especially between seasons

– Dropped tools or heavy machinery causing sudden impact

– Poor surface preparation before the epoxy was applied

– A thinning epoxy layer due to high foot traffic or ongoing use

Over time, concrete naturally shifts. Even subtle movements in the slab can stress the epoxy layer above it, leading to tiny surface cracks. This is even more likely when the temperature keeps jumping between hot and cold, which causes the surfaces to expand and shrink at different rates.

Industrial settings like mechanical workshops are especially prone to this. At one shop in regional New South Wales, heavy toolboxes and vehicle lifts were moved constantly. Over time, that concentrated weight weakened the surface. By the time they noticed, moisture had already made its way underneath, turning a small repair into a bigger job.

Sometimes, the issue starts with poor prep. If the concrete wasn’t dust-free or properly primed before the epoxy was laid down, the bond might not hold well. That poor grip underneath shows up as spider web cracking as time goes on.

Frequent foot or machine traffic can also wear down the coating until it becomes thin and more prone to damage. Recognising what’s causing the cracking helps you act earlier and avoid bigger problems later.

How to Identify Spider Web Cracks Early

The earlier you spot spider web cracks, the easier they are to fix. These cracks can blend into certain floor finishes, so it helps to know what to look for and where to check.

Keep an eye out for these visual signs:

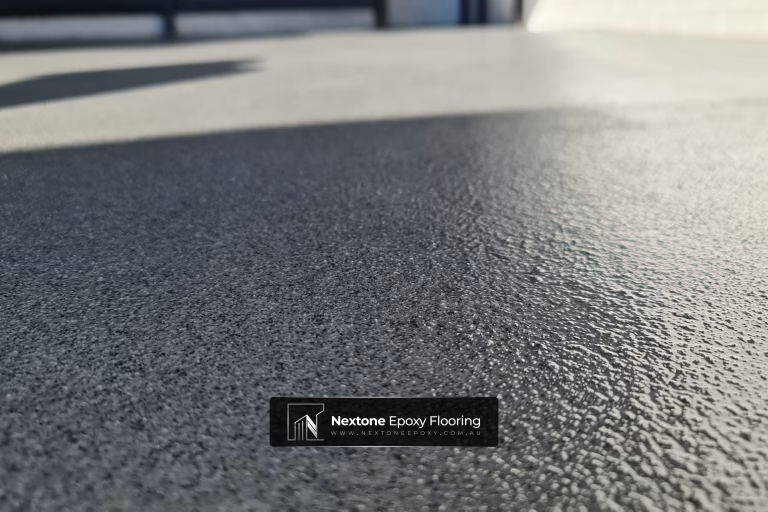

– Fine, curving lines that resemble spider webs or broken glass

– Areas that feel rougher than the rest of the floor

– Glossy parts looking dull or faded

– Dust or dirt settling into tiny cracks, making them stand out

– Multiple small cracks forming in one section

Pay attention to areas around heavy equipment, high foot traffic, and floor edges. These spots often take the most pressure and are the first to show stress or wear.

Get into a habit of checking your floors every few months. For industrial or commercial areas, you can space it out with other maintenance tasks. In homes or lighter-use zones, a check while cleaning is often enough.

Spotting cracks early isn’t just about appearances. Small floor flaws can grow into hazards or invite water and grime into hidden areas. If you start noticing a pattern, take photos and mark the location. This helps later if you need to brief a specialist for repairs or updates.

Steps to Take When You Notice Spider Web Cracks

Noticing spider web cracks is just the first step. What matters most is how you respond. These cracks don’t go away on their own, and waiting too long tends to make things worse.

Here’s what you can do if you catch spider cracks forming:

1. Stop using the damaged area if cracks have made it uneven or risky to walk across. Cut back on foot or machine traffic until the surface is checked.

2. Take clear pictures of the cracked parts. Note where they are, when you first saw them, and if anything changed recently—like temperature or floor usage.

3. Avoid patching the cracks yourself. DIY fixes can cover the surface but won’t address bigger issues under the coating.

4. Contact a professional epoxy flooring team. They’ll check whether the problem is shallow or linked to deeper damage.

5. Talk about repair or full reinstallation options. A new epoxy coat with proper prep can often handle both the look and the underlying issue.

Experienced flooring teams working across New South Wales have seen how local conditions affect epoxy finishes. Whether you’re dealing with temperature shifts inland or coastal exposure near salt air, they’ll tweak the process to suit your floor’s environment. Getting a professional opinion catches hidden problems early, so small cracks don’t turn into full-scale replacements.

Preventing Spider Web Cracks in the Future

Keeping spider web cracks from coming back is all about good care and preventative steps. Most surface damage shows up when floors are under ongoing stress or haven’t been maintained properly. With a few easy habits, you can reduce the chances of cracks forming again.

Here are some tips that can keep your floors in good shape:

– Clean up dirt and spills regularly so grit doesn’t work into the coated surface

– Put down mats in areas where machinery or loads are handled often

– Add expansion joints if the floor covers large spaces or meets other materials like wood or metal

– Limit temperature swings by sealing indoor areas and keeping air flow more consistent

– Book in routine inspections every 12 to 18 months to catch early signs before they get worse

One warehouse in outer Sydney kept seeing the same pattern. Every winter to spring, hairline cracks showed up again, no matter how often they patched them. After finally getting expert advice, they found out the slab underneath didn’t have any expansion relief. The epoxy coat was also too thin in some places. A full reapplication using proper joints and coating levels fixed it for good.

No matter what your floors are used for—from storing goods to operating forklifts—simple care goes a long way. Pairing regular attention with a solid installation process is the best way to keep things steady.

Keeping Your Floors Looking Great for the Long Haul

Spider web cracks are one of those things that creep up on even well-made epoxy floors. They often hint at stress, skipped prep during installation, or just heavy wear over time. But spotting them early and acting quick means you can avoid major hassles later.

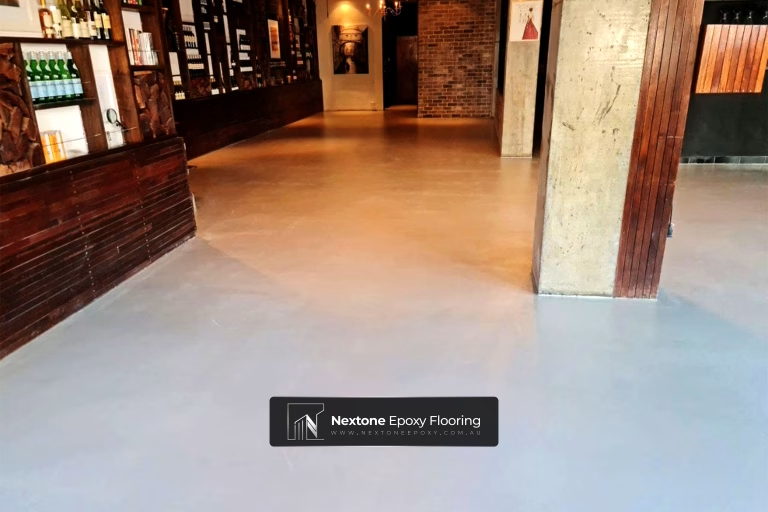

When your existing floor starts showing its age, or if you want your next installation done right the first time, it helps to work with people who understand these challenges. Epoxy floor installation in New South Wales, done by experts who know the local conditions, can restore your surface or give you a clean start that lasts longer.

Looking after these small signs now, keeping a basic maintenance plan in place, and investing in the right team can help your floors stay solid and good-looking for years. Whether you’re thinking about a fresh coat or just keeping tabs on wear and tear, early action always pays off.

To keep your floors looking and performing at their best, consider an expert assessment and service tailored specifically for your needs. Whether for your home or industrial premises, choosing the right professionals can make all the difference. Discover how epoxy floor installation in New South Wales can help you maintain a durable and crack-free floor with Nextone’s specialised solutions.