Running a warehouse means keeping things moving, and that includes everything from forklifts and pallet jacks to stacked goods and heavy machinery. With all that weight concentrated in one space, the floors have to be more than just tough. They have to be ready to handle the load day in, day out. That’s where epoxy flooring comes in. But even the strongest floors need to be used the right way. Knowing how much weight your epoxy floor can take isn’t just a nice-to-know detail—it’s a big part of keeping your operation safe and your flooring in good shape.

If the floor isn’t rated to handle the loads placed on it, cracks, dents or even full-on failure can follow. That can shut down work, damage gear or create serious safety risks for staff. The good news is, epoxy flooring can take quite a bit of punishment when installed properly and matched to the warehouse’s needs. But you’ve got to understand the limits. Getting this right helps you protect workers, equipment and the floor itself.

Understanding Epoxy Flooring Load Limits

Load limits are simply the amount of weight a surface can safely hold, whether it’s in one spot like under a racking leg or spread out across pallets. Epoxy flooring systems used in warehouses are built to handle different kinds of loads depending on the way they’re installed, the thickness of the layers and what’s underneath them. A floor that’s used for storing full pallets won’t need the same setup as one that sees heavy forklifts driving across it every few minutes.

Several things come into play when working out what an epoxy floor can handle. These include:

– Epoxy type: Some floors are made with lightweight coatings, while others use heavy-duty materials. The specific type of epoxy chosen affects overall strength.

– Cover thickness: A thin layer won’t offer the same load capability as a thicker one built up across several coats.

– Base layer: What’s under the epoxy counts just as much. If the concrete slab isn’t solid and clean to begin with, the strongest epoxy on top won’t make much difference.

Take a warehouse using medium-weight storage racks and the occasional forklift. For that, the best option might be a system with a thicker epoxy coating built on a well-prepared base. Pushing it beyond what it can handle—like bringing in heavier equipment or changing how space is used—can damage the surface unless it’s upgraded.

Safe load limits also depend on whether you’re dealing with static loads that don’t move or dynamic ones like vehicles and equipment. Regular forklift traffic puts stress on a floor in a different way than a pallet that’s been sitting in place for weeks. The more movement, the more pressure and wear you’re dealing with over time.

Being aware of what your flooring was meant to take helps with day-to-day decisions. If you plan to rearrange the space or bring in new gear, checking whether the flooring can handle it should always be part of the process.

Factors Affecting Load Capacity

Load limits don’t just come down to the epoxy alone. The whole flooring system, from the material it’s made of to how it’s applied and where it’s located, all plays a part in how much weight it can bear.

1. Substrate Quality

If the concrete base underneath isn’t strong, the epoxy coating won’t be either. A cracked or worn-down slab will shift and move under pressure, making even the best coating fail faster. Proper surface preparation is key. That means removing old coatings, repairing weak spots and getting the surface clean and dry before any resin goes down.

2. Epoxy Type and Thickness

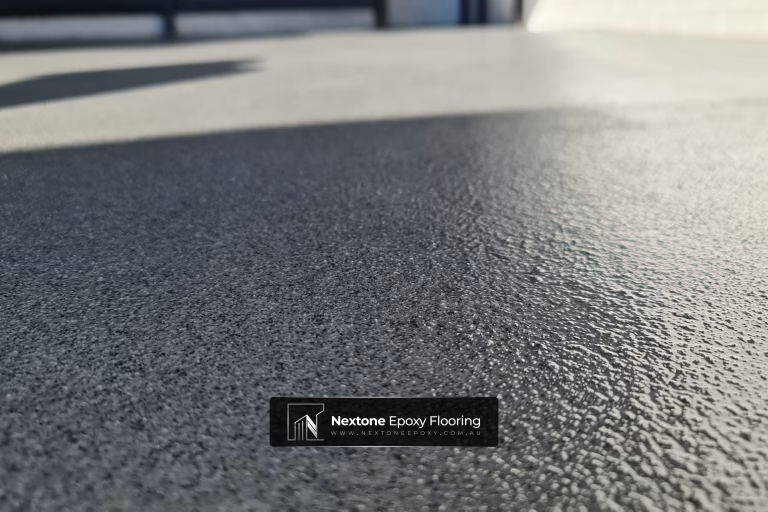

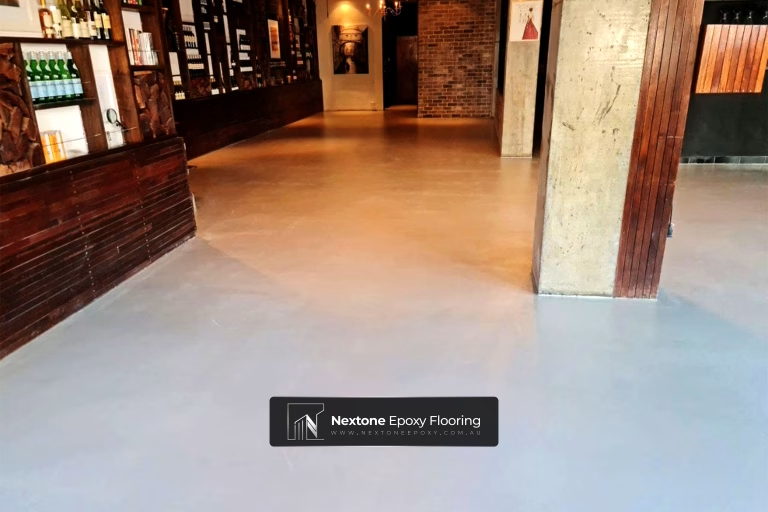

Each epoxy formula is made for a different job. Thin roll-on coatings might be fine for a backroom or showroom, but they won’t last in a busy warehouse. Thicker applications with added aggregates like grit or quartz can better handle heavy vehicle traffic and stop quick damage from dropped goods or constant tyre wear. The number of coats and how they’re applied also matters. More layers build strength and give the coating a deeper bond with the substrate.

3. Environmental Conditions

Warehouses don’t always sit in perfect conditions. Some locations are more humid. Some floors are exposed to sunlight near roller doors, extreme cold near freezers or water near washdown zones. These conditions put constant pressure on the coating. Epoxy will expand and contract with temperature shifts. If it’s not suited to your site’s environment, the floor may peel, bubble or show early signs of wear. It’s important to pick a formulation based on the local climate and known exposure points.

If your operations change or expand, these factors should be reviewed again. A new racking layout or heavier equipment might mean your current system no longer holds up. That’s when expert re-evaluation can help make sure the floor still aligns with your evolving workload.

Assessing Your Warehouse Needs

To choose the right epoxy flooring system, you need to know what happens across your warehouse each day. Load capacity isn’t just about how much something weighs. It’s about where it goes, how it moves, and how often it’s dragged, wheeled or pushed across the floor.

Start by breaking the floor plan down into different usage zones. Think about:

– Static load zones: These are areas under shelves, racking or machines that don’t move. These spots face long-term stress and need very high load support.

– Dynamic load routes: Aisles and entryways where staff, forklifts or pallet jacks are constantly on the move. Coatings here must resist wear, tyres and vibration.

– Special conditions: Includes sections near loading docks, wash bays, freezer units or open doors. They need extra moisture and temperature resistance.

Let’s say you run a parts warehouse with shelving packed tightly together and forklifts taking tight turns in narrow aisles. Those corners and junctions will wear faster than anywhere else. Planning the flooring to handle that workload is what makes the difference between a surface that lasts five years and one that needs patching in just a year or two.

If you know heavier stock is coming soon or you’re investing in new machinery, now’s the time to check load limits and surface requirements. Preparing ahead of time helps avoid early damage or disruptions down the line.

Maintaining Optimal Performance

Even with a solid installation, epoxy floors don’t take care of themselves. With regular use, wear builds up slowly—and without regular checks, small problems can turn into expensive ones. A smart maintenance plan helps keep the floor strong and safe, no matter what kind of work it’s doing.

Here are five simple tips to keep epoxy flooring working well:

1. Stick to a cleaning schedule

Use gear that won’t scratch or damage the coating. Avoid harsh chemicals and use neutral cleaners suited to epoxy surfaces. Keep walkways clear of grit and dirt to prevent abrasion.

2. Check for wear and marks

Walk the floor regularly and spot check for cracks, scrapes or peeled areas. Discolouration can also be a sign of moisture or chemical damage underneath the surface.

3. Fix small problems early

A hairline crack or chipped edge might not seem pressing, but these can lead to moisture leaks or coating breakdown. A quick patch now saves money and prevents downtime.

4. Watch problem-prone zones

Entry points, dock areas, spots under shelves or tight turning spots for forklifts are usually the first to wear. Focus on checking these areas more often.

5. Stay aware of load changes

If new equipment gets added or stock becomes denser over time, the floor’s needs might shift. Regularly review how the space is used versus what it was originally designed for.

Good flooring isn’t just about the moment it’s installed. It’s about how it’s used, and whether you keep up with it. Maintenance isn’t about being perfect—it’s about catching things before they turn into costly problems.

Making the Most of Your Epoxy Flooring Investment

Epoxy flooring is a strong and reliable option for warehouses, but only when it’s matched to the actual workload of the space. Safe load limits aren’t just a feature—they’re a key part of operation planning. If the floor is rated below the weight it’s handling, any savings in instalment can quickly get wiped out by early repairs, downtime or even accidents.

Taking time to understand how your space functions, what types of loads are common, and where the high-wear areas sit helps create a concrete plan (literally and figuratively) for durable, long-lasting flooring. And when things change—as they often do in busy warehouse environments—it pays to bring in someone who can help determine if your current floor can still handle the job.

Being proactive doesn’t mean spending more. It means knowing what to expect and being ready for it. The result is increased safety, reduced damage and a flooring system that keeps the entire operation steady under pressure.

To make sure your warehouse operates smoothly, choosing the right epoxy flooring for warehouses makes all the difference. Nextone specialises in durable, custom-fit solutions that suit the everyday demands of busy industrial environments. Let our team help you build a safer, more efficient workspace with flooring that’s built to last.