Epoxy floors are built to last. They’re known for their durability, sleek look, and low upkeep. But just like any surface that sees daily use, epoxy floor systems can start showing signs of wear. Timely repairs are key to making sure small problems don’t turn into big, costly issues.

Knowing the early signs of damage helps protect your floors and maintain both safety and appearance. Whether you’re managing a workshop, warehouse, or showroom, it pays to keep an eye out for trouble before it gets worse. Here are some common signs that your epoxy floor might benefit from professional attention.

Visible Cracks And Chips

One of the most obvious signs that your epoxy floor needs repair is when cracks or chips start showing up. These surface issues are usually caused by heavy impacts, ageing, or sudden shifts in temperature that expand or contract the concrete below.

Cracks often start small, but that doesn’t mean they should be ignored. If moisture or dirt gets into the cracks, it can loosen the bond between the epoxy and the concrete. That leads to more damage over time and can affect both the strength and safety of the floor.

Here are a few situations where cracks or chips might appear:

– Equipment being dropped on the floor

– Forklifts or heavy trolleys constantly moving over the same area

– Poor surface prep during the original application

– Expansion or shrinkage from exposure to heat or cold

Even if it looks like a minor surface issue, it can signal deeper problems. Cracking is sometimes a hint that the epoxy layer has lost its adhesion or that the concrete slab underneath is shifting. Instead of patching it up over and over, a professional can assess whether the floor still has good structure underneath or if it’s time for a fresh start.

Discolouration And Staining

Epoxy flooring is designed to resist spills and stay looking its best with minimal effort. But when the surface starts to change colour, it’s often more than just a cosmetic issue. Discolouration can mean that a chemical has broken through the top layer or that the protective seal is starting to wear out.

You might notice your once-clear or glossy epoxy floor now has patched spots that look yellow, dull, or cloudy. Some of the most common causes for this include:

– Spilled acids or harsh cleaners

– Oil or grease that wasn’t cleaned up quickly

– UV exposure in areas that get direct sunlight

– Standing water left for long periods

One example is when oils or harsh cleaning agents from a commercial kitchen sink into the surface, leaving behind dark stains that seem impossible to clean. Over time, this eats away at the resin finish, causing both colour change and a loss of surface performance.

When staining is paired with a rough texture or flaking, it usually means the surface layer has failed. That’s a sign it’s time to call in a professional to inspect the coating and restore the protection your floor needs.

Peeling Or Bubbling

When sections of your epoxy floor start to peel or bubble, it’s a strong sign that something’s not right underneath the surface. These issues usually pop up when the bond between the epoxy coating and the concrete base starts to fail. That failure could be from poor surface prep at the start, trapped moisture during installation, or pressure from below the slab.

Bubbling looks like raised pockets on the floor and can sometimes feel soft or hollow underfoot. Peeling, on the other hand, shows as flaking layers or shredded edges, which can quickly catch machinery wheels or shoes. In both cases, what you end up with is an uneven surface that’s hard to clean, prone to holding dirt, and harder to walk or work on safely.

These signs should be tackled sooner rather than later. Ignoring them lets more debris and moisture get under the damaged parts, eating away at the remaining epoxy. Instead of trying to keep patching it up, consider having the floor inspected and repaired properly by a professional who can reapply the finish where needed and prevent the same thing from happening again.

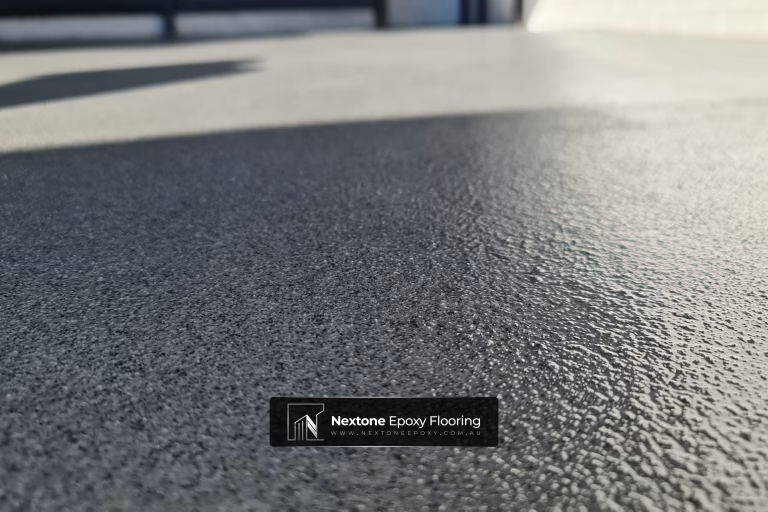

Increased Slipperiness

Epoxy floor systems are usually slip-resistant. That’s one of the reasons they’re so popular in places where safety matters, like warehouses, kitchens, and showrooms. But if you’ve noticed that your floor feels much slicker than it used to, there could be a bigger issue underneath and it’s worth taking seriously.

Loss of slip-resistance might come from:

– Worn down topcoat or sealer

– Oil or moisture trapped in surface textures

– Incorrect cleaning with harsh chemicals

– Damage causing uneven wear

If staff or visitors have started slipping in spots that used to have better grip, it’s time to look under the surface. Uneven wear won’t always look obvious, but it can affect how lighting bounces off the floor or how it feels when you walk over it. A proper anti-slip texture can’t be restored with a quick mop or a new mat. Reapplying a slip-resistant coating might be the safer and longer-lasting fix.

Constant Repair Needs

There’s a big difference between an occasional fix and a never-ending patch-up job. If minor damage keeps showing up every few months, it probably means your epoxy floor has aged out of its former strength. This is especially common in high-traffic areas like commercial garages or loading bays.

Ongoing small repairs might include:

– Filling small chips repeatedly

– Repainting worn patches

– Reapplying topcoat in the same zone again and again

These fixes might feel cheaper or easier in the short term, but over time they can add up not just in cost, but in downtime too. It’s usually more practical and cost-effective to have the floor assessed for a full recoat or fresh system. That way, you’re not wasting time or money on band-aid solutions.

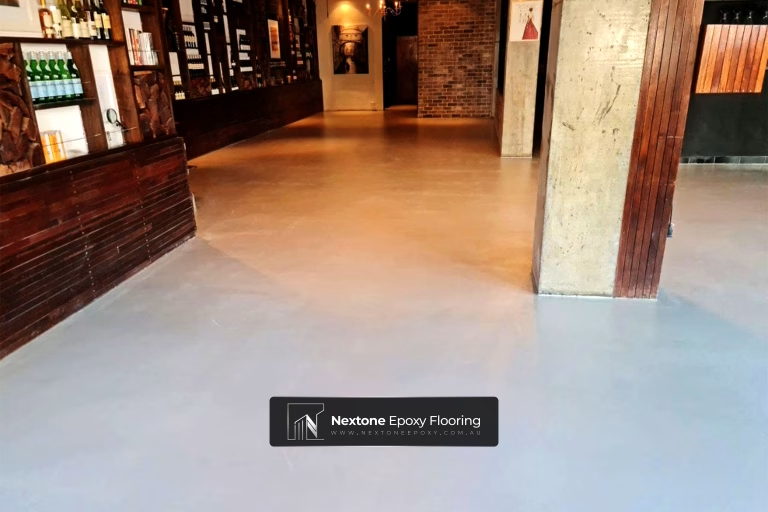

Keep Your Epoxy Flooring In Top Condition

Spotting damage early makes all the difference. Cracks, stains, and slippage aren’t just surface issues; they can point to bigger wear that affects the entire epoxy floor system. Acting fast helps protect your space and can keep downtime and interruptions to a minimum.

Every floor goes through wear and tear, but when these signs start piling up, it’s best to go with a long-term fix. Whether your epoxy has lost its grip, started bubbling, or needs repairing over and over again, it could be time for a full review. A professional can let you know what’s still working and what needs attention so your epoxy surface stays durable, safe, and looking good.

Keeping your epoxy flooring in great shape helps create a safer, more reliable space for everyone. If you’ve started noticing signs of wear, it could be time to take a closer look. Gaining a better understanding of how epoxy floor systems work and how they should perform over time can help you decide when it’s time for repairs or upgrades. At Nextone, we’re here to make sure your flooring continues to support your space and your goals.